- Transmitter connects to any PureAire toxic or corrosive gas sensor

- The remote cable allows for gas monitoring 10, 20, or up to 30 feet from the transmitter

- Plug & Play sensor sets the transmitter gas & measurement range

- Dual-level user-adjustable alarm relays

- 4-20mA analog output

- Built-in horn & visual alarm LEDs

- Electronics continuously check sensor & systems status

- Low-cost, long-life renewable sensor

- Quick, easy sensor calibration

- Connects to PLC or SCADA controller

- UL, CUL, and CE Approvals

- 24V DC Power supply included

- Available without a built-in horn – 99090. Please contact PureAire for ordering information, 847-726-6000

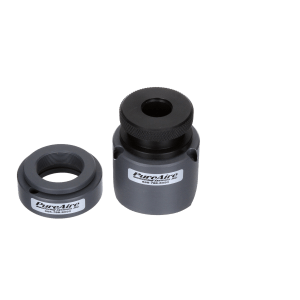

The PureAire Universal Gas Detector is a compact gas monitor that’s ideal for protecting workers from toxic and corrosive gas exposures in the workplace. It consists of a generic transmitter/controller connected to a dedicated, renewable gas sensor that automatically inputs the gas and measurement range. Designed as a stand-alone monitor, the Universal Gas Detector can also be connected to any programmable logic controller or SCADA system.

The heart of the system is a smart renewable sensor cell that’s programmed with the specific gas and measurement range information. Simply plug the sensor into any Universal Gas Detector transmitter and it’s ready to go. When servicing the sensors, they can be recharged with fresh electrolyte and dynamically gas calibrated in the maintenance shop away from the transmitter.

Low Annual Operation Cost

The Universal Fixed Gas Detector has the lowest annual maintenance costs of any gas monitoring system on the market. PureAire Renewable sensors are easily recharged with electrolyte right in the field at approximately 20% of the cost of disposable sensor cell-type systems. Routine maintenance materials are $70 per year and when compared to the high cost of disposable sensors, can save you hundreds of dollars in annual service!

Stand-Alone Monitoring

The Universal Gas Detector is designed to operate totally stand-alone. Just mount it to the wall near the risk site, plug it into any 115VAC 60 Hz outlet or 220VAC 50 Hz outlet using the included power supply cord, and the Monitor will begin measuring gas levels after a brief warmup period. The built-in horn and LED alarm indicators quickly alert personnel to hazardous conditions. It also has individual alarm and fault relays for connecting remote alarms or control and the analog 4-20mA output provides continuous data to remote PLC and SCADA systems.

Continually supervised electronics

The Universal Gas Detectors’ “smart” circuitry is continuously supervised 24-7 and should a system error occur, the detector’s analog output and fault relay immediately alert control room personnel to the problem. A dedicated microcontroller built directly into the sensor allows you to remove from it the transmitter for all routine calibration and maintenance. Calibration data is directly entered into the sensor electronics and then transferred to the transmitter once it’s plugged in.