- 99020 – Suitable for Class 1, Div 1 & 2, Groups B, C, D, Zones 1 & 2, Groups IIB+H2, IIA

- 99045 – Suitable for Class 2, Div 1 & 2 Groups E, F, G

- Long-life 10+ year average sensor life

- Two-alarm relay setpoints available or alarm defaults are set for 19.5% and 18.0%

- No scheduled maintenance required

- 3-year warranty

- Digital display

- 4-20mA analog output (Active)

- No Drift due to thunderstorms or barometric pressure changes

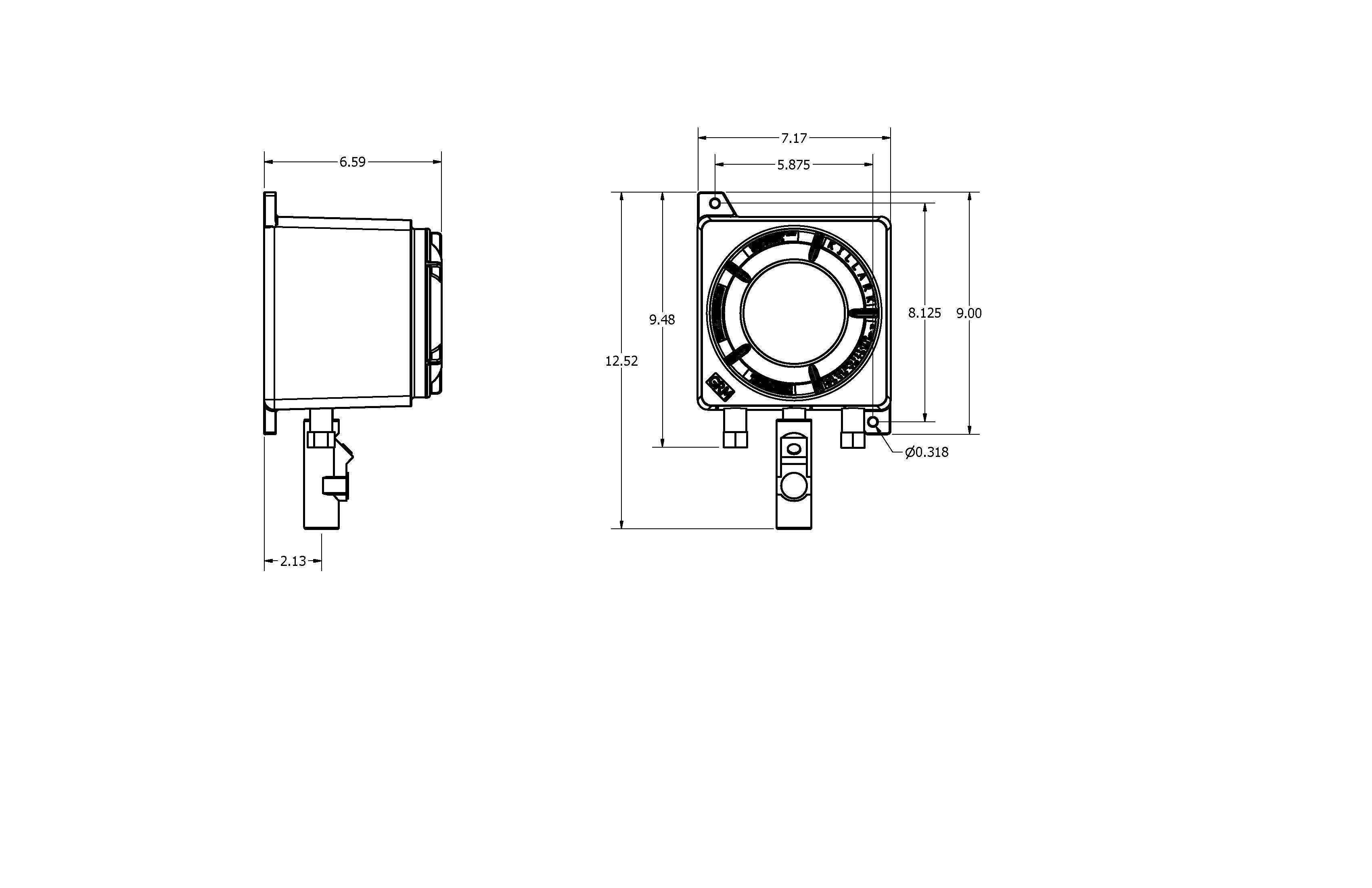

- Wall mounting brackets

- Built-in flow sample pump up to 100ft

- CE, UL, and C UL approval on enclosure

The Explosion Proof Oxygen Monitor offers long-lasting O2 deficiency detection. PureAire’s oxygen monitors are reliable, affordable, low maintenance, and provide continuous monitoring for an average of 10 years and more.

Ideal for use in electrically classified locations, confined spaces, analyzer shelters, petrochemical plants, cryogenic gas storage, and locations requiring remote sampling. The EX oxygen monitor can detect leaks of inert gases such as nitrogen, helium, and argon. The explosion-proof oxygen monitor can detect gas leaks at temperatures as low as -40C.

The monitor features an easy-to-read local display, visual LEDs, and an audible alarm. The oxygen monitor can be linked to fire alarm systems for notification of all employees.

The zirconia sensor is not sensitive to temperature, humidity, or barometric pressure changes (including thunderstorms). Unlike other oxygen monitors, replacement sensors are not required, since we use a zirconium sensor, rather than a disposable electrochemical sensor lasting 1-2 years on average. “Supervised watchdog,” software runs 24/7 checking electronics and components. Any errors or inconsistencies are reported on the display.

By installing PureAire’s explosion-proof oxygen monitor, you can save as much as $400 annually and reduce the time-intensive cycle of replacing sensors.